Choosing the right panel maker affects the quality and life of your cold storage facility. Good panels keep products safe, lower energy costs, and limit repairs. This guide explains what to check when you select a cold storage panel manufacturer in Africa.

Check Experience in Cold Storage Panels

Look for a maker with real experience in cold storage panels. Cold storage requires tight temperature control and moisture resistance. A manufacturer with history in this area knows how to meet these needs. Ask how long they have worked with cold storage products.

Look for Quality Materials

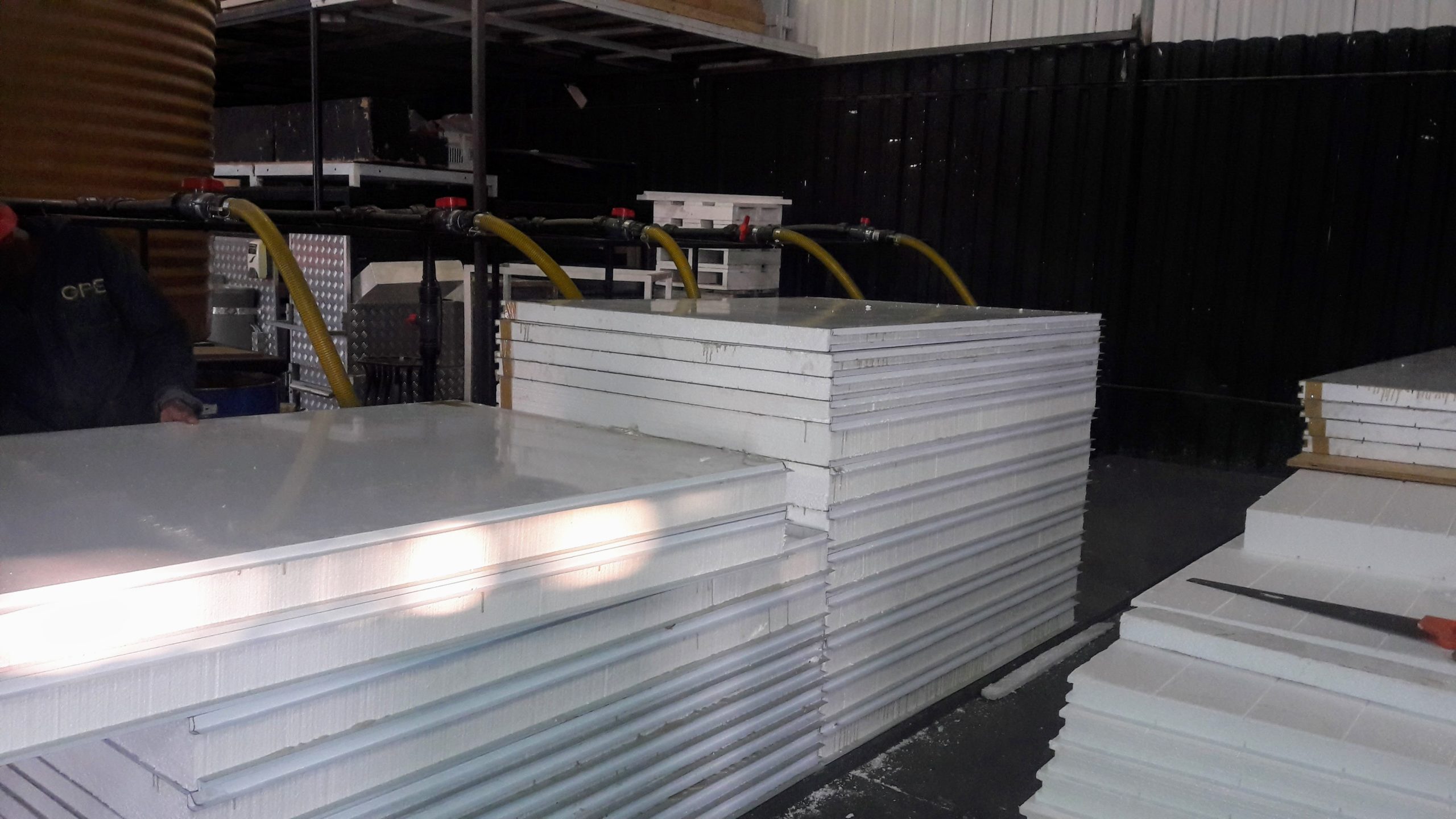

Panels must use strong and stable materials. These materials affect heat control, strength, and long-term performance.

Key material checks:

- Insulation type and thickness.

- Facing materials that resist corrosion.

- Joints that seal air and moisture.

Good materials reduce damage and lower energy use.

Verify Compliance with Standards

Cold storage panels must meet building and safety rules. Ask the manufacturer if their panels meet local and international standards. Standards ensure safe performance. Compliance protects your facility and products.

Ask About Thermal Performance

Thermal performance shows how well panels stop heat flow. Better thermal control means the cooling system works less and saves energy.

Request:

- R-values or U-values.

- Test reports.

- Case studies of past projects.

This data shows how the panels perform in real conditions.

Evaluate Manufacturing Capacity

The maker must produce panels reliably and on time. Check if they have:

- Modern machines.

- Consistent quality control.

- Enough staff for large orders.

A strong operation means fewer delays and consistent products.

Check Installation Support

Panels must fit well to work well. A manufacturer that helps with installation adds value. Look for:

- Installation guides.

- On-site support.

- Trained technicians.

Good support reduces mistakes and speeds up construction.

Look for After-Sales Service

Cold storage panels may need service after installation. Ask about:

- Warranty terms.

- Replacement parts.

- Service response times.

Fast and clear support helps fix issues before they grow.

Review Local Presence and Logistics

In Africa, transport and delivery can affect cost and timing. A manufacturer with local presence or distribution points can:

- Deliver faster.

- Lower freight costs.

- Provide better on-ground support.

Local ties improve overall experience.

Compare Costs and Value

Price matters, but look at value too. Low cost with poor quality leads to high long-term expense. Compare:

- Material quality.

- Performance data.

- Warranties.

Choose a partner that offers long-term savings, not just a low price.

Seek Customer Feedback

Ask for references or read reviews. Real customer feedback shows how the maker performs on:

- Delivery times.

- Product quality.

- Support responsiveness.

This helps you make a smarter choice.

Final Tips

Make a list of your needs before you speak with manufacturers. Clear needs help you compare suppliers fairly. Choose a partner that promises quality, support, and reliable delivery. Good panels start with a maker who cares about performance and service.