Cold storage facilities in Africa face harsh operating conditions. Heat, humidity, unstable power, and limited maintenance cause frequent failures. These failures lead to product loss, high energy use, and short building life. Engineered panel systems reduce these risks through clear design and material control.

Heat Gain from External Temperatures

Many regions in Africa experience high daily temperatures. Heat enters cold storage buildings through walls, roofs, and joints.

Common problems include:

- Thin insulation.

- Gaps between panels.

- Poor roof insulation.

Engineered panel systems prevent heat gain by using:

- Adequate insulation thickness.

- Continuous insulation across walls and roofs.

- Precision-made joints with tight seals.

These features keep internal temperatures stable. Cooling systems work less and last longer.

High Humidity and Moisture Damage

Humidity is a major cause of cold storage failure. Moist air enters the building and condenses on cold surfaces. This creates water, ice, and corrosion.

Typical failures include:

- Rust on metal parts.

- Mold growth.

- Swollen or damaged insulation.

Engineered panel systems control moisture by:

- Adding vapor barriers within panels.

- Sealing joints to block humid air.

- Removing thermal bridges that cause cold spots.

Dry panels maintain strength. Clean surfaces support food and medicine safety.

Power Instability and Temperature Fluctuations

Power cuts and voltage changes are common in many areas. Each outage causes temperature rise. When power returns, systems cool the space again. This cycle stresses the building.

Frequent issues include:

- Panel movement from expansion and contraction.

- Cracked joints.

- Loss of airtightness.

Engineered panel systems reduce damage by:

- Using materials that handle low temperatures.

- Keeping insulation uniform to limit temperature swings.

- Designing joints that stay sealed during movement.

Stable panels help the facility recover faster after outages.

Air Leakage and Energy Loss

Air leaks raise energy use and reduce cooling efficiency. Warm air enters. Cold air escapes.

Leak sources include:

- Poor panel alignment.

- Weak joint design.

- Low-quality installation.

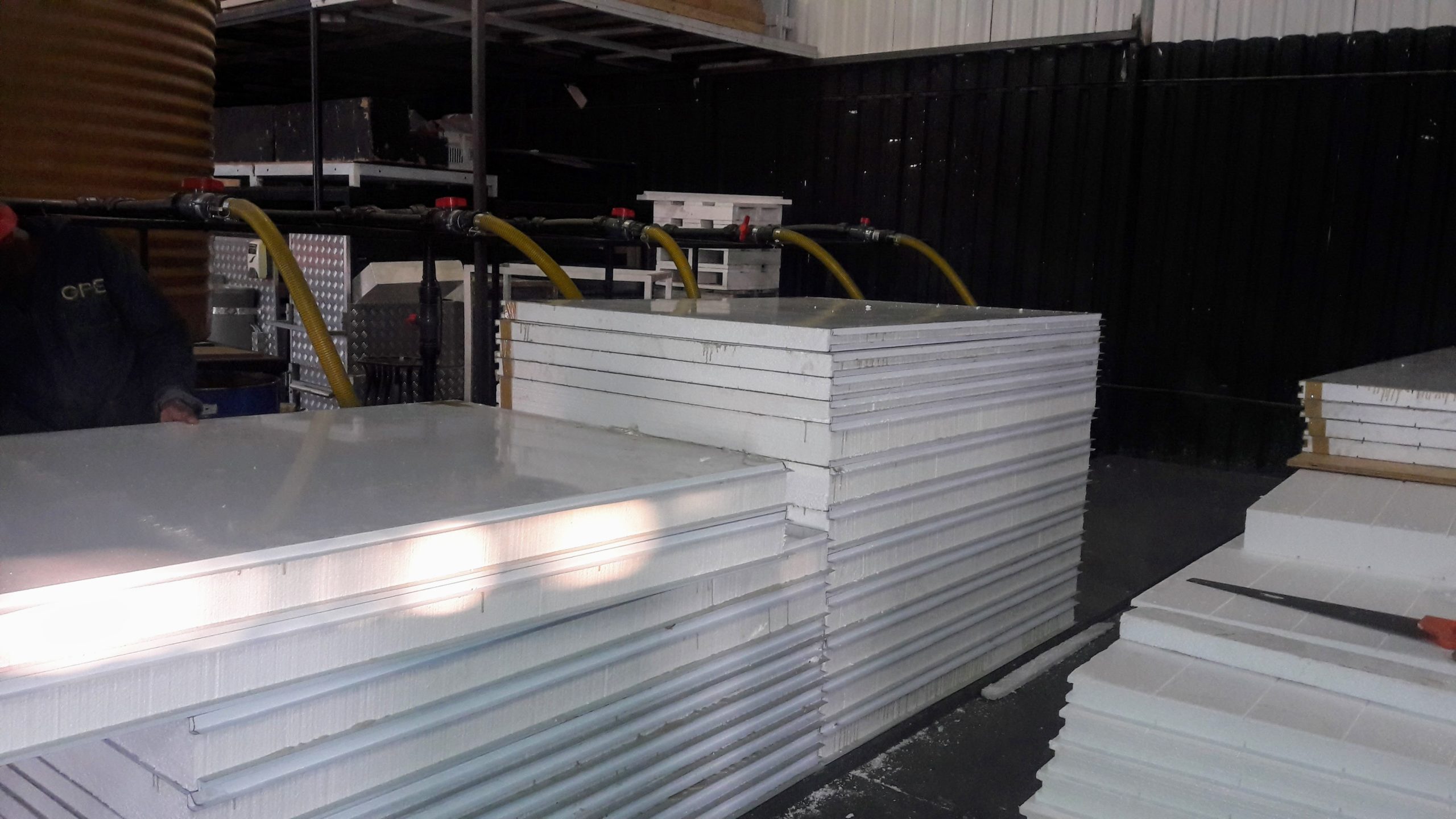

Engineered panel systems prevent leaks through:

- Factory-made panels with accurate dimensions.

- Interlocking joints that lock panels in place.

- Clear installation methods that reduce errors.

Better air control lowers power demand and protects stored goods.

Structural Wear and Early Failure

Cold storage buildings carry heavy loads. Racks, products, and roof systems place constant stress on panels.

Common structural failures include:

- Panel bending.

- Joint separation.

- Roof sagging.

Engineered panel systems improve strength by:

- Matching panel size to load limits.

- Using strong facings that protect the insulation core.

- Spreading loads evenly through the correct fixing points.

Strong panels keep the building safe and stable for long periods.

Maintenance Challenges

Many facilities face limited access to skilled maintenance teams. Small issues often go unnoticed until they cause major damage.

Typical problems include:

- Hidden moisture inside walls.

- Worn seals.

- Surface damage from cleaning.

Engineered panel systems simplify maintenance by:

- Using smooth, cleanable surfaces.

- Allowing easy panel inspection.

- Supporting fast panel replacement when needed.

Simple maintenance reduces downtime and repair costs.

Product Loss and Hygiene Risks

Failures in temperature or moisture control lead to spoiled goods. This affects food safety, medicine quality, and business trust.

Engineered panel systems protect products by:

- Keeping temperatures stable.

- Preventing condensation and ice buildup.

- Supporting clean interior conditions.

Reliable storage reduces waste and protects supply chains.

Final Thoughts

Cold storage failures in Africa often come from heat, humidity, power issues, and maintenance limits. Engineered panel systems address these challenges through clear design and material control. They protect the structure, reduce energy use, and extend building life.

Facilities that invest in proper panel systems gain stable performance. They also gain better product safety and lower long-term costs.