Cold storage facilities protect food, medicine, and other sensitive goods. These buildings depend on insulated panels to control temperature. A clear and well-planned panel design increases building life, cuts costs, and improves safety. This post explains how proper insulated panel design achieves these results.

What Insulated Panels Do

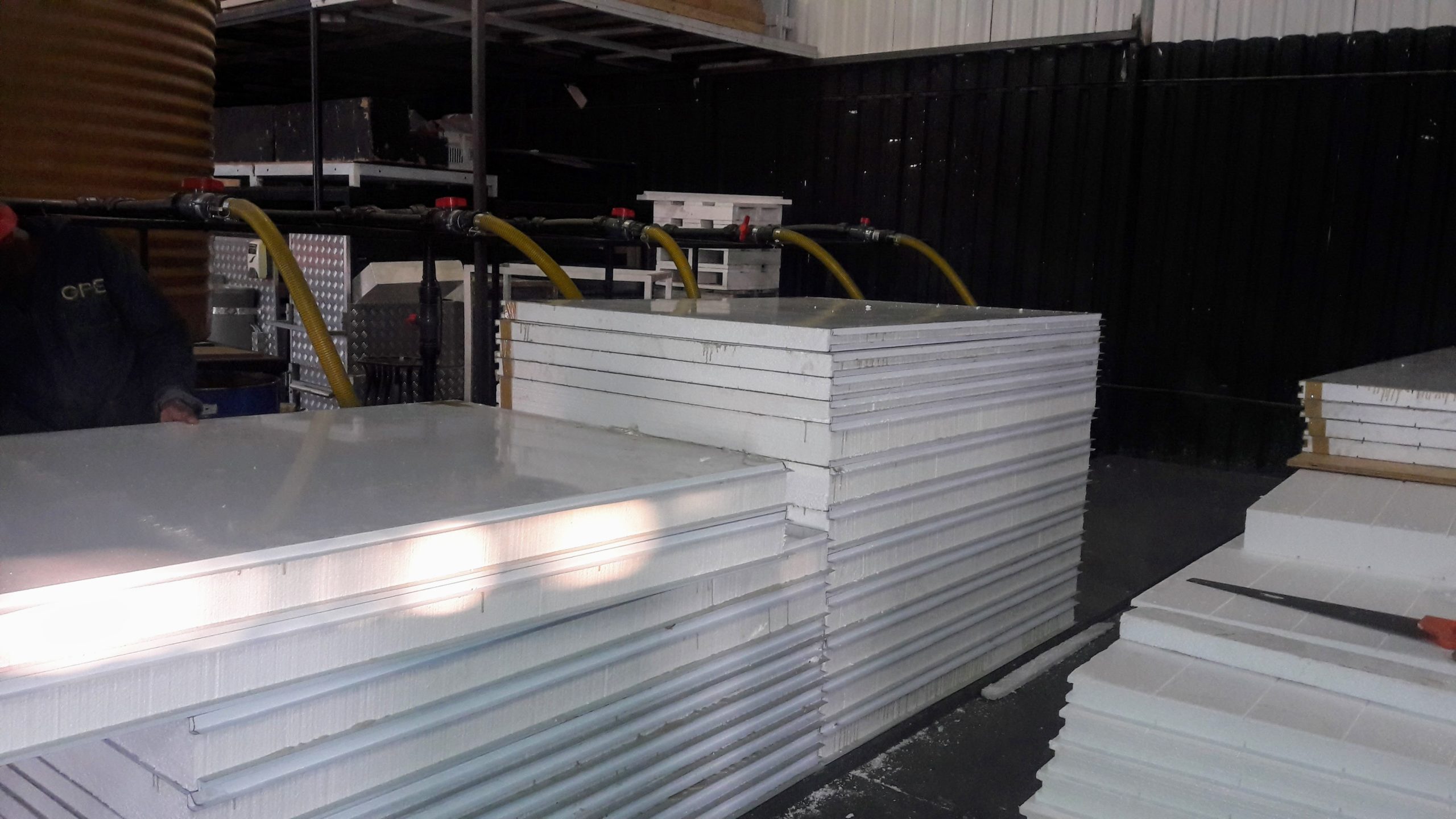

Insulated panels form the walls, ceilings, and sometimes floors of cold storage buildings. Each panel has an outer layer, an inner layer, and insulation in between. The panel slows heat transfer. The panel also blocks moisture and air leaks. These actions protect the structure and the stored goods.

Why Panel Design Matters

Panel design affects how long a facility lasts. A poor design allows heat, moisture, and air to enter. These problems cause wear and damage. A proper design controls these risks from day one.

Control of Heat Transfer

Heat moves from warm areas to cold areas. Insulated panels slow this movement.

- Thick insulation reduces heat flow.

- Continuous insulation removes gaps.

- Tight panel joints stop air leaks.

When heat stays out, cooling systems work less. Less work means less strain. Equipment lasts longer. Panels also face fewer temperature swings. This reduces cracks and warping.

Moisture Control and Condensation Prevention

Moisture causes serious damage in cold storage buildings. Water leads to corrosion, mold, and ice buildup.

Proper panel design controls moisture in several ways:

- Vapor barriers stop moisture from entering the panel.

- Sealed joints block humid air.

- Correct panel placement avoids cold bridges.

These steps prevent condensation inside walls. Dry walls stay strong. Metal parts resist rust. The building keeps its shape and strength for many years.

Structural Strength and Stability

Panels must support their own weight and resist outside forces. Wind, roof loads, and daily use place stress on the structure.

Good design supports strength:

- Strong facings protect the insulation core.

- Proper fastening spreads loads evenly.

- Panel size matches span limits.

Stable panels do not bend or shift. This protects seals and joints. The building stays airtight and solid over time.

Reduced Thermal Cycling Stress

Thermal cycling occurs when temperatures rise and fall. This movement causes expansion and contraction.

A proper panel design limits this stress:

- Uniform insulation keeps temperatures steady.

- Correct materials handle low temperatures well.

- Secure joints allow slight movement without damage.

Reduced stress lowers the risk of cracks. Fewer cracks mean fewer repairs. The facility stays in service longer.

Energy Efficiency and Equipment Life

Efficient panels reduce energy loss. Cooling systems run fewer hours. Motors, compressors, and fans face less wear.

This benefit extends facility life in two ways:

- Lower energy use cuts operating costs.

- Reduced equipment strain delays replacement.

A building that costs less to run is easier to maintain. Owners can invest in upkeep instead of constant fixes.

Hygiene and Surface Protection

Cold storage facilities must meet strict hygiene rules. Panel surfaces play a key role.

Proper design includes:

- Smooth interior surfaces that clean easily.

- Materials that resist stains and bacteria.

- Sealed edges that block debris.

Clean surfaces prevent damage from harsh cleaning chemicals. Panels keep their finish and strength for longer periods.

Ease of Maintenance and Repair

A clear panel system simplifies upkeep. Workers can inspect, clean, and repair panels with less effort.

Good design supports maintenance:

- Standard panel sizes allow easy replacement.

- Accessible joints speed up inspection.

- Durable finishes reduce repair frequency.

Simple maintenance extends service life. Small issues get fixed before they grow.

Long-Term Cost Savings

All these design choices affect costs over time. A longer lifespan means fewer rebuilds and less downtime.

Savings come from:

- Lower energy bills.

- Fewer repairs.

- Longer equipment life.

- Reduced product loss.

These gains support steady operations and reliable storage conditions.

Final Thoughts

Proper insulated panel design plays a direct role in the lifespan of cold storage facilities. The design controls heat, moisture, and stress. It supports strength, hygiene, and energy efficiency. Each benefit adds years to the building’s life.

Facility owners who focus on panel design protect their investment. They also protect the goods inside. A clear, simple design choice today leads to stable performance for many years ahead.